Kanban complements goal-first product management. As a product manager, you set the product strategy that determines feature priority upfront. Teams pull new features from the backlog as capacity allows and add them to in-progress work. You can also apply tags or labels to indicate which strategic imperative each work item supports.

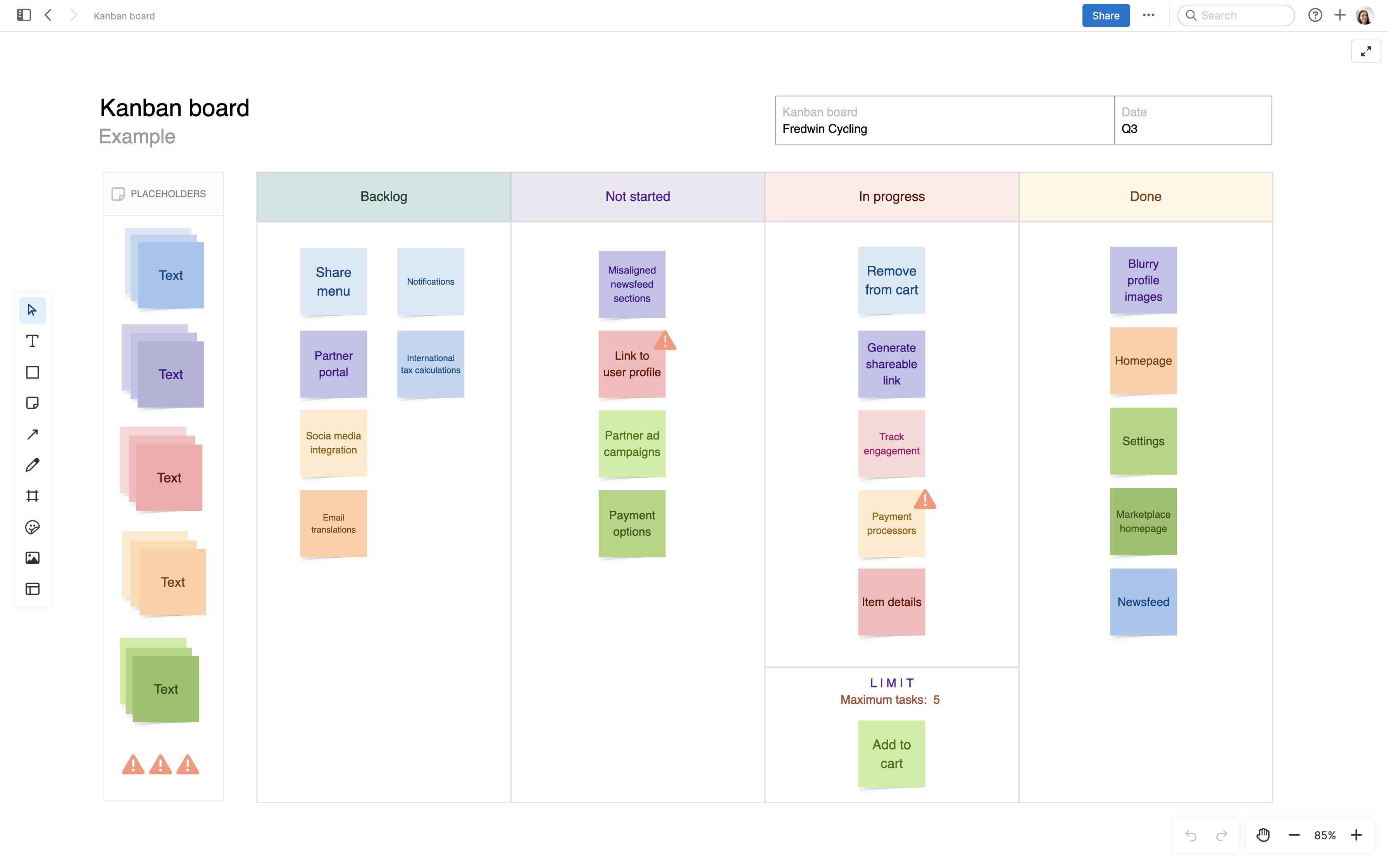

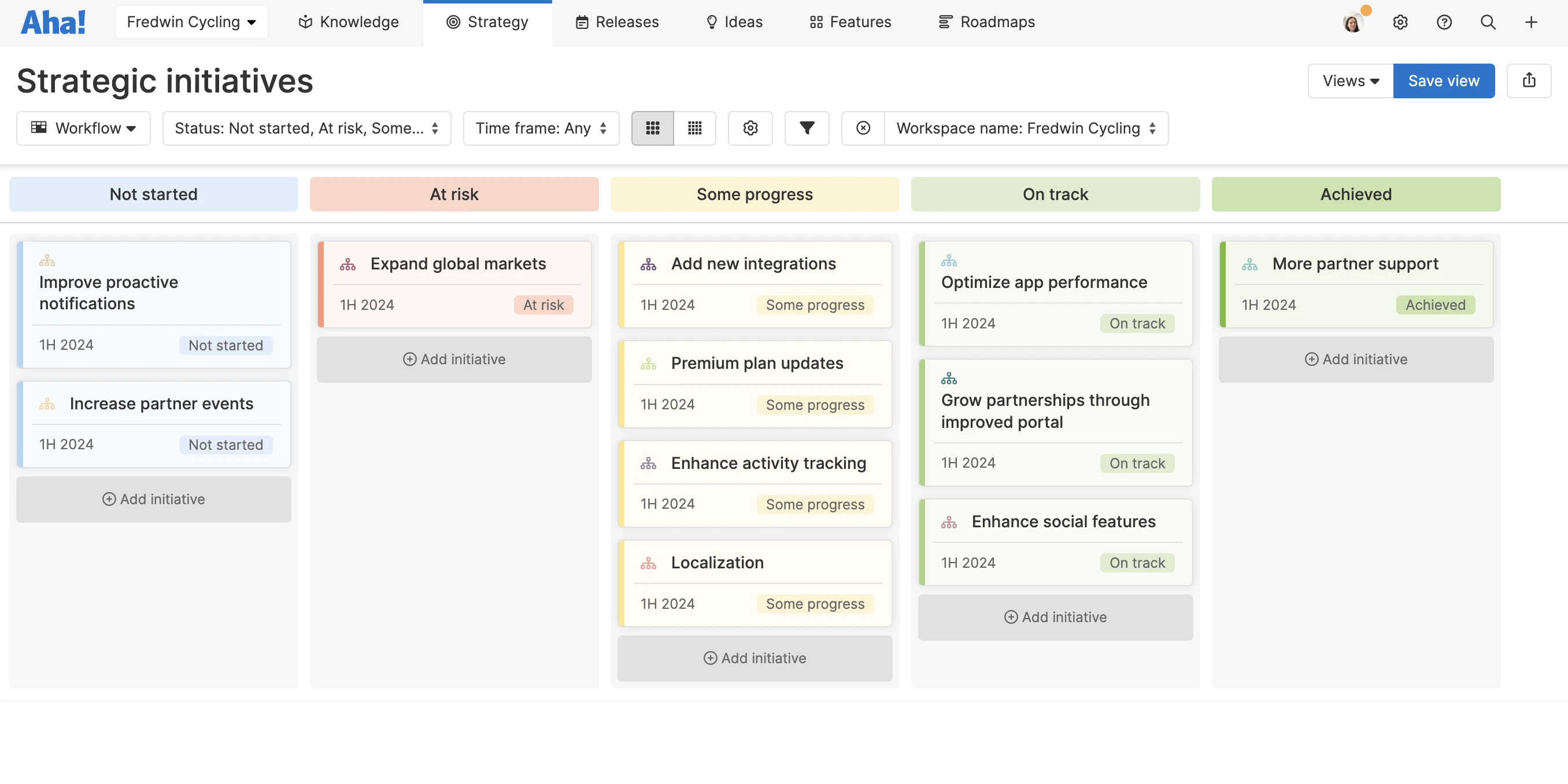

Kanban teams use a physical or digital kanban board to map out a team or organization's workflow. Vertical lanes or columns visualize each step in the workflow. Column labels can be as simple as “Not started," "Some progress," and "Achieved," or you can choose terminology that is unique to a specific workflow. Work items are represented by cards that are moved from left to right across the board to show how each work item is progressing within the workflow.

In this guide, we cover a few ways product managers can leverage kanban to support successful product development. Keep on reading, or use the following links to jump ahead:

(For a more in-depth review of how product managers set up and optimize a kanban board, check out this guide.)

Product development

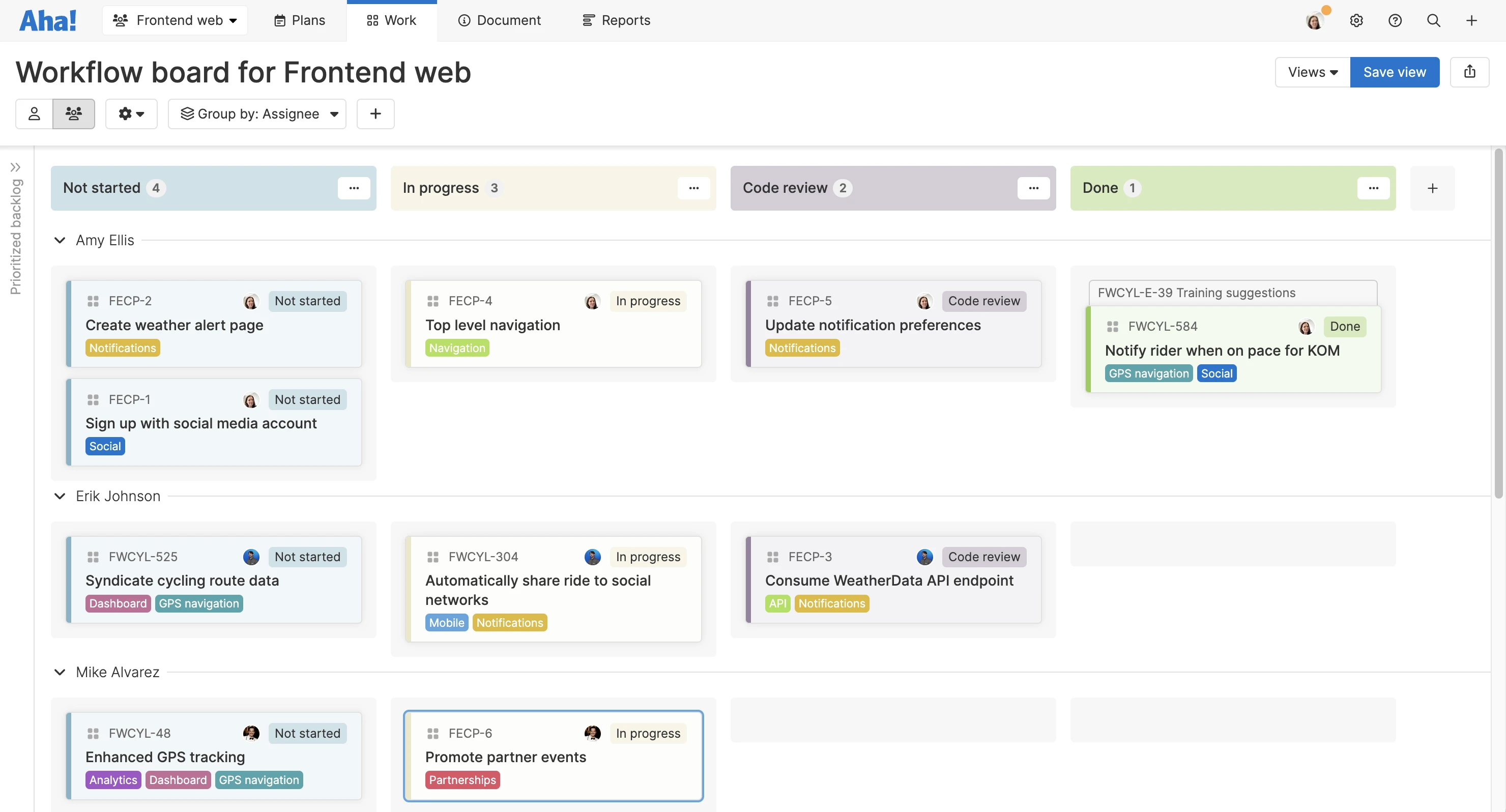

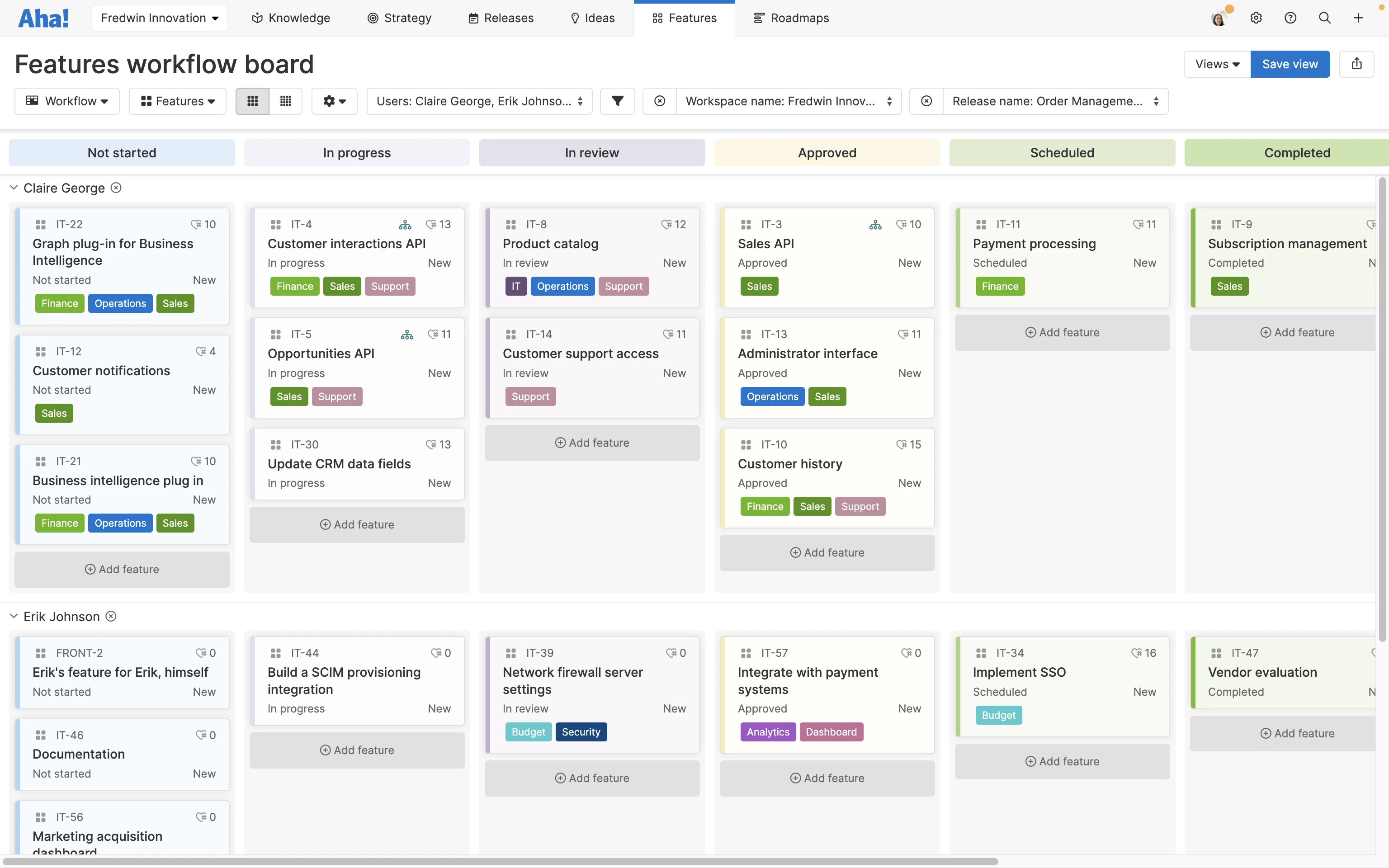

Product managers and engineers often collaborate using kanban boards. In this scenario, a product manager prepares features and requirements in a "Ready for development" (or similar) column of a kanban board and partners with the engineering manager to ensure the backlog is prioritized.

Engineers then choose cards to pull into their workload as capacity allows and within the board's work-in-progress limits. Adding swimlanes to the kanban board, organized by engineer, can help both the product manager and engineering manager better understand the team's workload and identify bottlenecks.